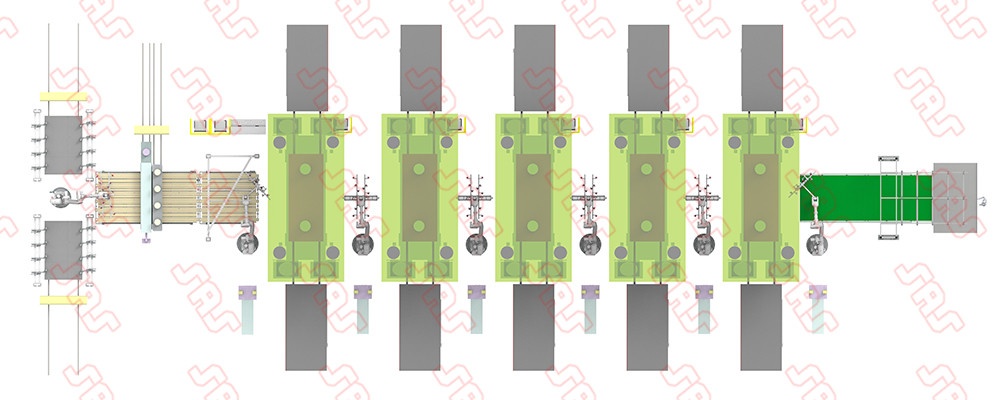

Seven-axis robot stamping line

Press intermittent mode production, the production cycle can reach 13SPM per minute

Composition:

Line head depalletizing unit 2x mobile destacking trolleys 2x Manual Magnetic Arm Automatic Spreading System 1x 6-axis robot 1x depalletizing end picker (universal) 1x Double Sheet Detection System 1x feeding belt conveyor Cleaning the oiling unit (optional) 1x washing machine 1x Oiler Web centering unit 1x transition belt conveyor 1x Vision Belt Conveyor 1x visual alignment system Feeding unit 1x 6-axis robot 1x Loading Robot End Picker (ATC) | Transfer unit between presses 4x 7-axis robot 4x Transfer Robot End Picker (ATC) End of line receiving unit 1x 6-axis robot 1x Unloading Robot End Picker (ATC) 1x Receiving belt conveyor 1x through the tail light bracket and quality inspection table (optional) Safety protection unit 1x whole line safety fence 1x full line safety lock and control Electrical control unit 1x total control system 7x QuickStamp special software for stamping robot automation |

Main parameters:

Press spacing (recommended) 5.5-7.5m

Maximum production cycle 13SPM

Optional:

Production line MES production management system Production status display system Video Surveillance System Robotic Magnetic Arm Automatic Spreading System | Pneumatic Magnetic Arm Automatic Spreading System End-of-line automatic packing system Line end vision automatic detection system |